3D printing gives designers the power to create products using digitally designed models that do not have the constraints of conventional physically fabricated models. These prototypes are fast and more cost effective than traditional manufacturing methods, and allow for realistic simulations of a 3D model.

Examples include proof-of-concept prints, tabletop miniatures, and detailed organic models.

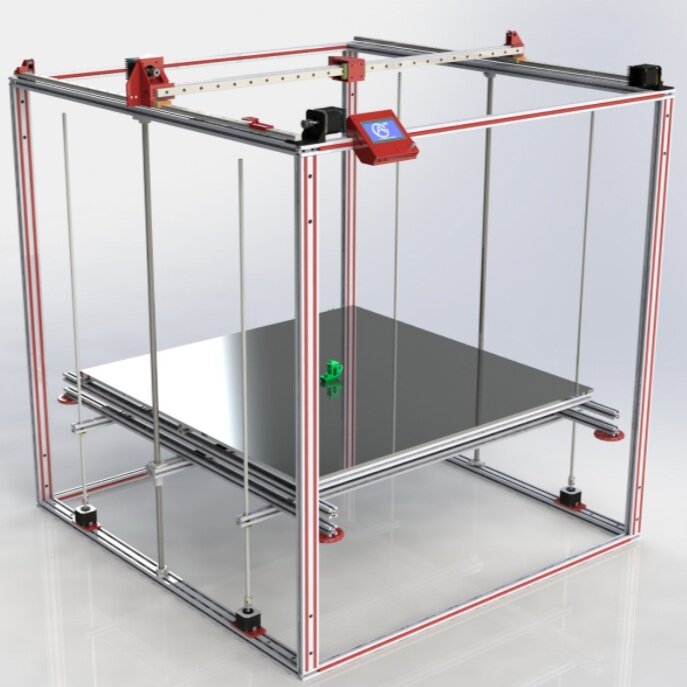

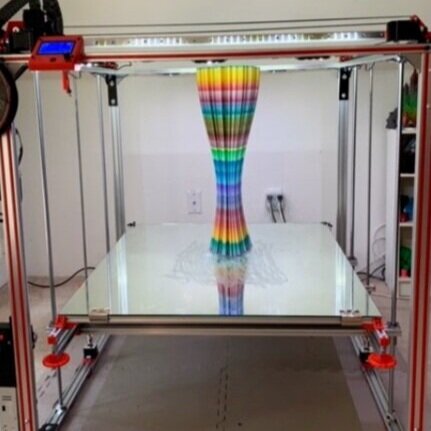

Replik8 Studios offers a unique service: the AG3D Colossus. With a print volume of 37,000in³, this massive FDM printer can create single parts sixty times larger than the average printer. This is optimal for large, load-bearing, parts.

The average FDM 3D printer has a maximum print volume of about 700in³ – the size of a standard shoe box. Larger print volumes are available, but max out at around 7,500 in³ for consumer-level machines.

In some cases, thermoplastic parts may not provide the strength, durability, or heat resistance required for more heavy-duty prototypes. Replik8 Studios provides metal 3D printing services, allowing for the creation of prototypes, or end-use parts, with the material properties of various common metal alloys.

We are excited to use our expertise to help you design the product or solution you need.